Final Project

Purus

Every year 270 billion litres of water are used in washing machines in the UK alone. Furthermore 350,000 tonnes of clothing that is used but still wearable is thrown into landfill every year.

Purus is a device to clean and remove spot stains from clothing quickly and efficiently. The device uses five times less water per garment than a standard washing machine.

Saving Water, Energy and Costs One Wash at a Time

Purus is a cheaper more efficient alternative to cleaning stains from clothing. Due to increasing energy costs, consumers spend thousands on energy bills each year. During the cost of living crisis this device helps cut back on energy and water consumption ultimately reducing costs significantly. The handheld device is clamped over the stain to provide a focused, localised wash. The fabric sits between the waste tank and the washer unit enabling it to be cleaned efficiently.

A Faster and More Sustainable Alternative

Purus operates using a water pump which forces a mixed solution of detergent and water into the fabric to remove the stain. The brush setting powers a motor to oscillate the silicone brush which agitates the stain. A fan is used to force the moisture through the fabric and dry the stain. The clean garment is ready to wear in under 15 minutes, nine times faster than a washing and drying cycle.

A Closer Look

Displaying the interface and logo on the product in detail. The simple interface is clear to help users understand the function of each control as it is a novel product.

Journey to the Show

Specialising in the branding of the product. Purus is a sustainable brand with the aim to revolutionise the way consumers approach clothing stain removal by providing an innovative, efficient and sustainable solution. Developing the brand to advertise it commercially along with it’s biodegradable packaging.

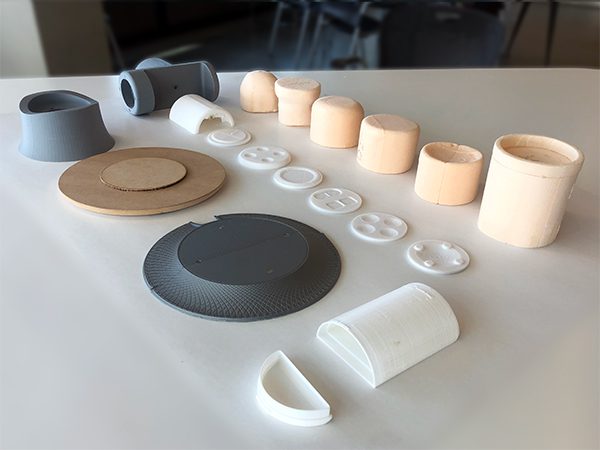

Creating prototypes to test and evaluate with potential users. Ranging from low to high fidelity models to display the design process and make iterations throughout.

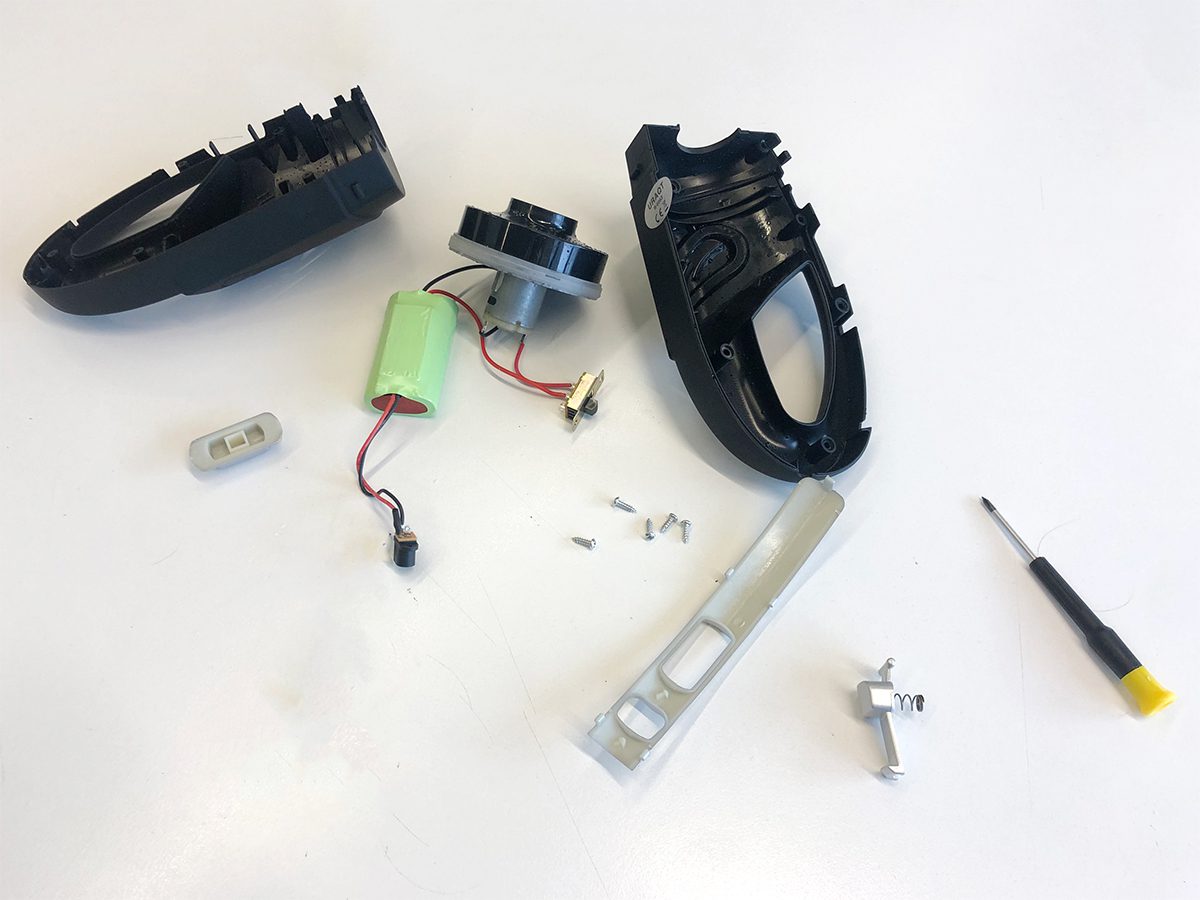

Disassembly of existing products to understand its components and assembly. Analysing the product part by part to ensure it is appropriate for mass manufacture.

Other Work

AIO- A one week project provided by DCA Design in which the brief was “To propose a physical product that a brand could launch to enrich lives and aid the cost of living crisis.”. AIO is an All In One personal care device for Philips.

The problem is consumers spend thousands of pounds on personal care devices over their lifetime including single use products which heavily contribute to landfill. The device aims to reduce the cost of personal care devices and enhance personal care routines whilst decreasing cost and landfill contribution.

The device consists of a universal soft touch handle which powers the different heads. With five different attachments it accommodates for all users. Simply charge the device on the dock and change the head necessary for your personal routine.

Awards

- 23′ Design Week – DCA Brief 3rd Place

- 23′ RSA Design School Shortlist

- 22′ Diploma of Professional Studies

Work Experience

Sept 21′- June 22′ CWD London, Designer

I gained valuable experience working in a design consultancy fully immersing myself in the design process. Working with a team of designers and various clientele helped build my communication and design skills in the process in order to meet tight deadlines.

Visionary Thinkers

Visionary Creators

Visionary Makers