I'm at my best when I'm creating combined working and aesthetic prototypes of medical devices in an additive manufacturing environment. I've got a borderline addiction to electronics, and I enjoy DfA.

Outside design, I love cycling, hiking and language learning.

Final Project

The Calmette-Phisalix Antivenom Autoinjector

Snakebites kills 100,000 people per year and leaves 400,000 more permanently disabled. It’s estimated that around 40% of deaths occur without the victim ever reaching hospital.

Inspired by recent advances in mRNA and synthetic antibody technology, the Calmette-Phisalix injector guides laypeople through the process of antivenom reconstitution and administration, buying them vital time for their journey to hospital.

Improving Survival Chances

The multilingual UI helps patients enter the recovery position and gives research-backed advice to increase bite survivability.

A victim’s first instinct is often to apply a tourniquet to a snakebite or to try and suck out the venom – but these treatments have no medical benefit and they can often make symptoms significantly worse.

Highly Portable

The device is designed for use in the field. Treatment is reconstituted on-demand and kept in inert cartridges until it’s needed.

If the device loses power, the Luer-compatible treatment cartridges can be easily removed for manual delivery in an emergency.

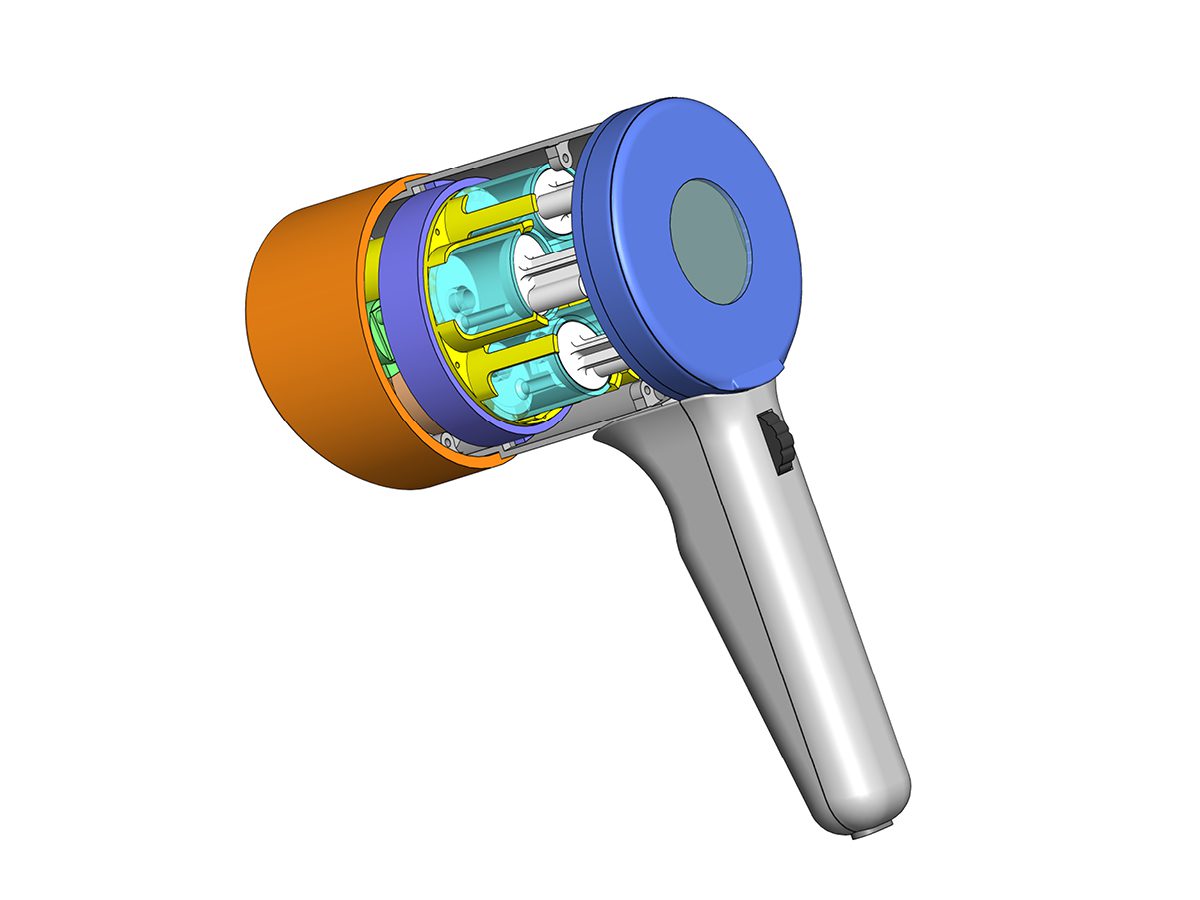

Solidworks Assembly

Designed with accurate tolerances for MSLA prototype production.

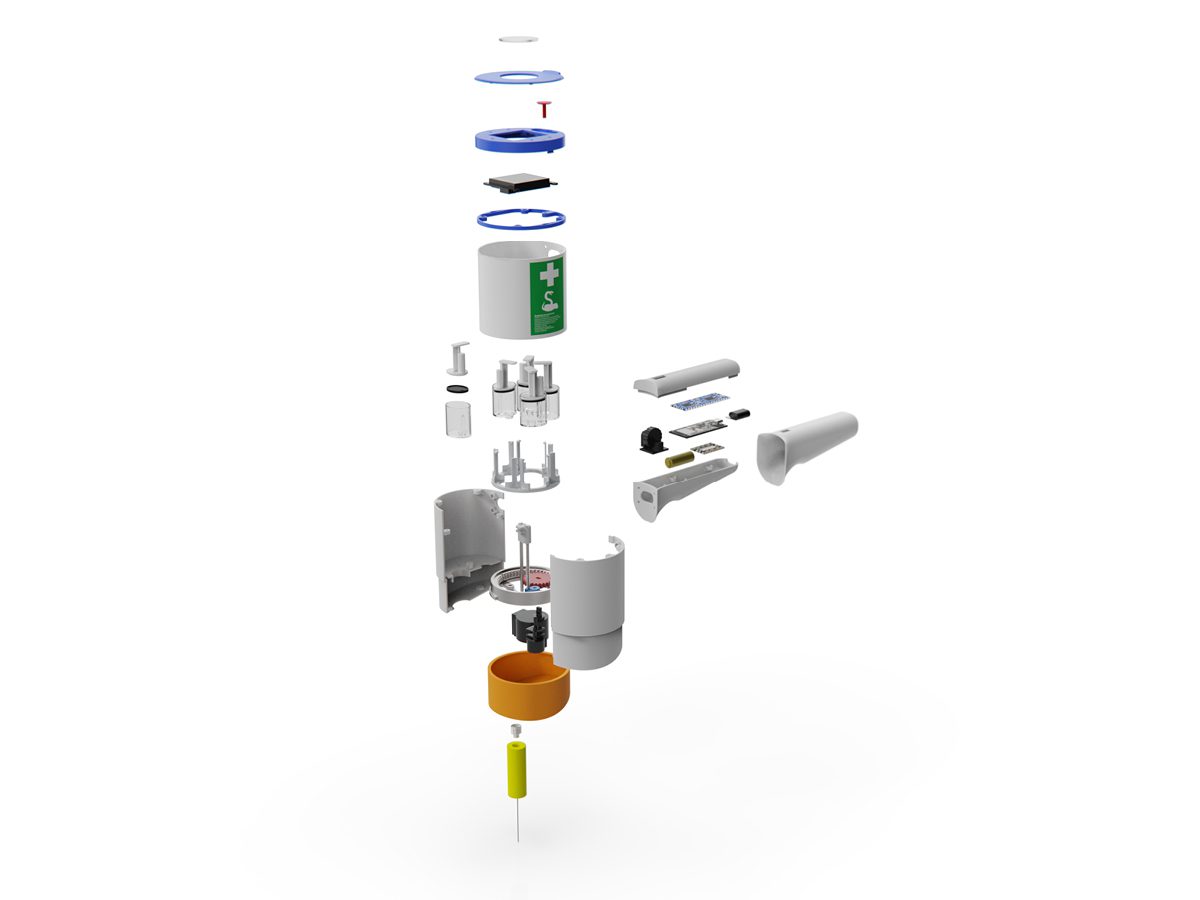

Exploded View

The lid assembly can separate in an emergency to allow access to the treatment cartridges. The cartridges snap-fit into the rotating carousel to facilitate easy removal.

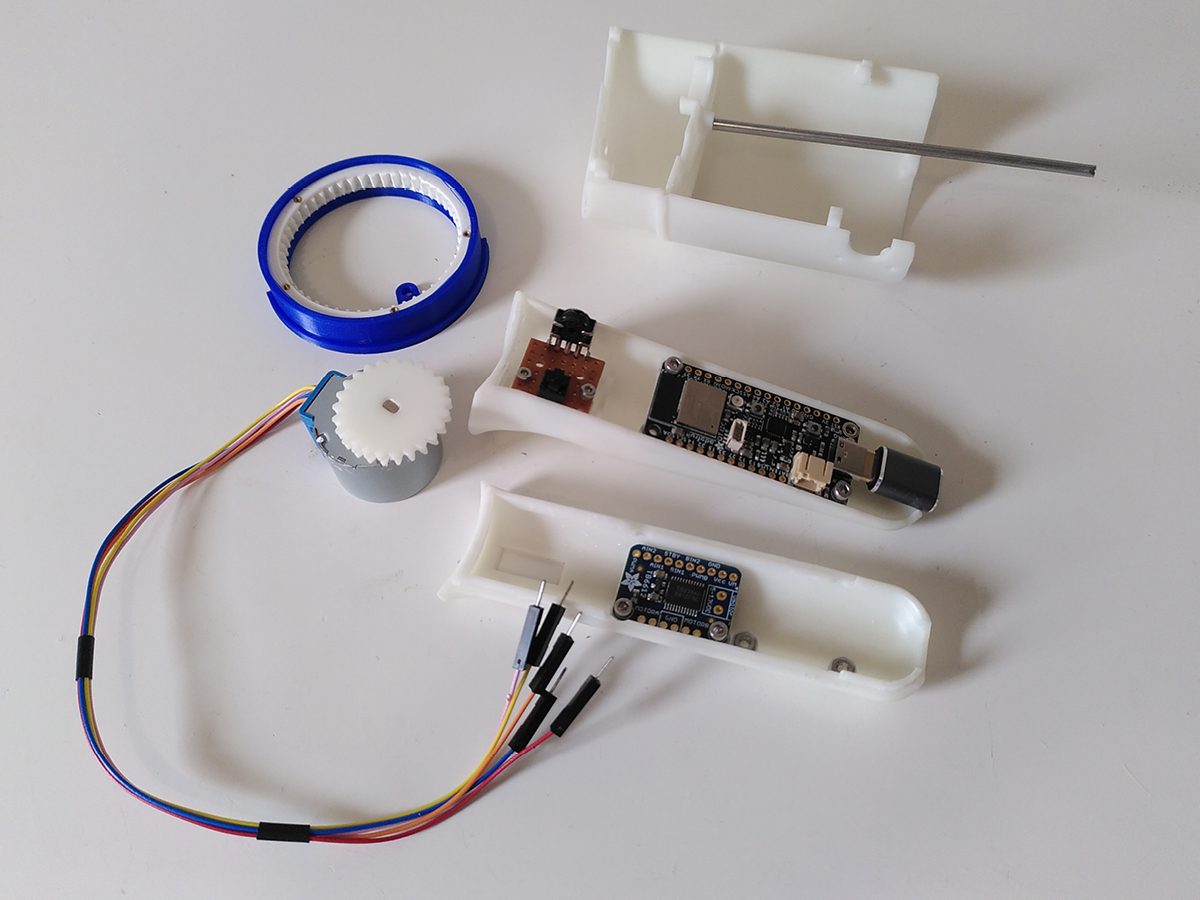

Internals

The prototype is driven by an ESP32 microcontroller and two TB6612 motor driver boards in the handle. It’s controlled by a combination rotary encoder and button PCB. The treatment cartridges spin on a print-in-place slewing bearing designed specifically for the prototype.

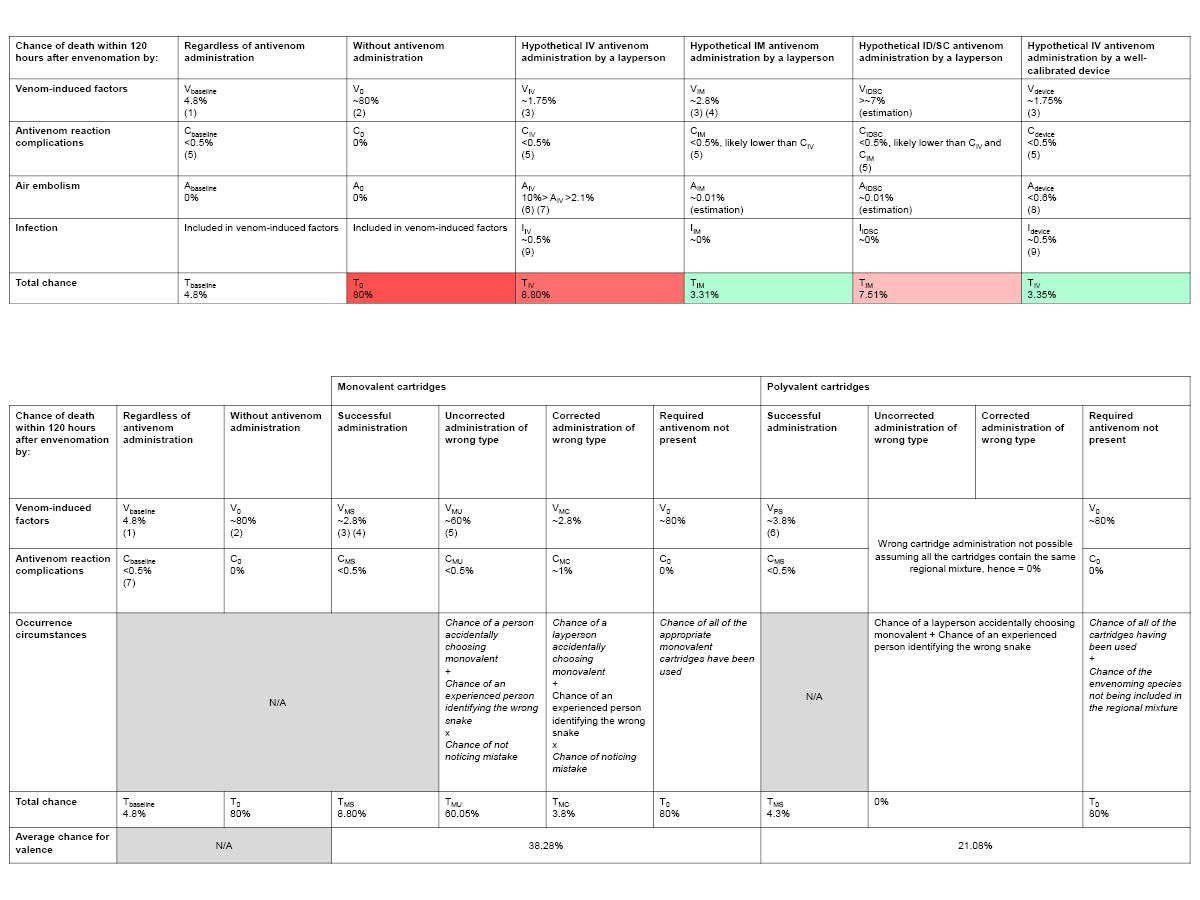

Rigorous Efficacy Analysis

The design direction was informed by conversations with experts at the WHO and a Kenyan antivenom distributor. The best available data was analysed to confirm the appropriate administration route and treatment valence.

Other Work

Skin Cancer Treatment Device

A working prototype of a medical device for the non-invasive treatment of skin cancer, produced on placement at UW Designs.

The At-Home Auto Biopsy Kit

Winner of the PDD live brief award.

The kit allows patients to painlessly collect a sample of a lesion without the need for a needle. It facilitates earlier detection of conditions like Melanoma, saving lives and reducing the complexity of excision surgery due to metastasis. More than 50,000 punch biopsy procedures could be managed, and completed entirely remotely, without any risk of patient non-attendance.

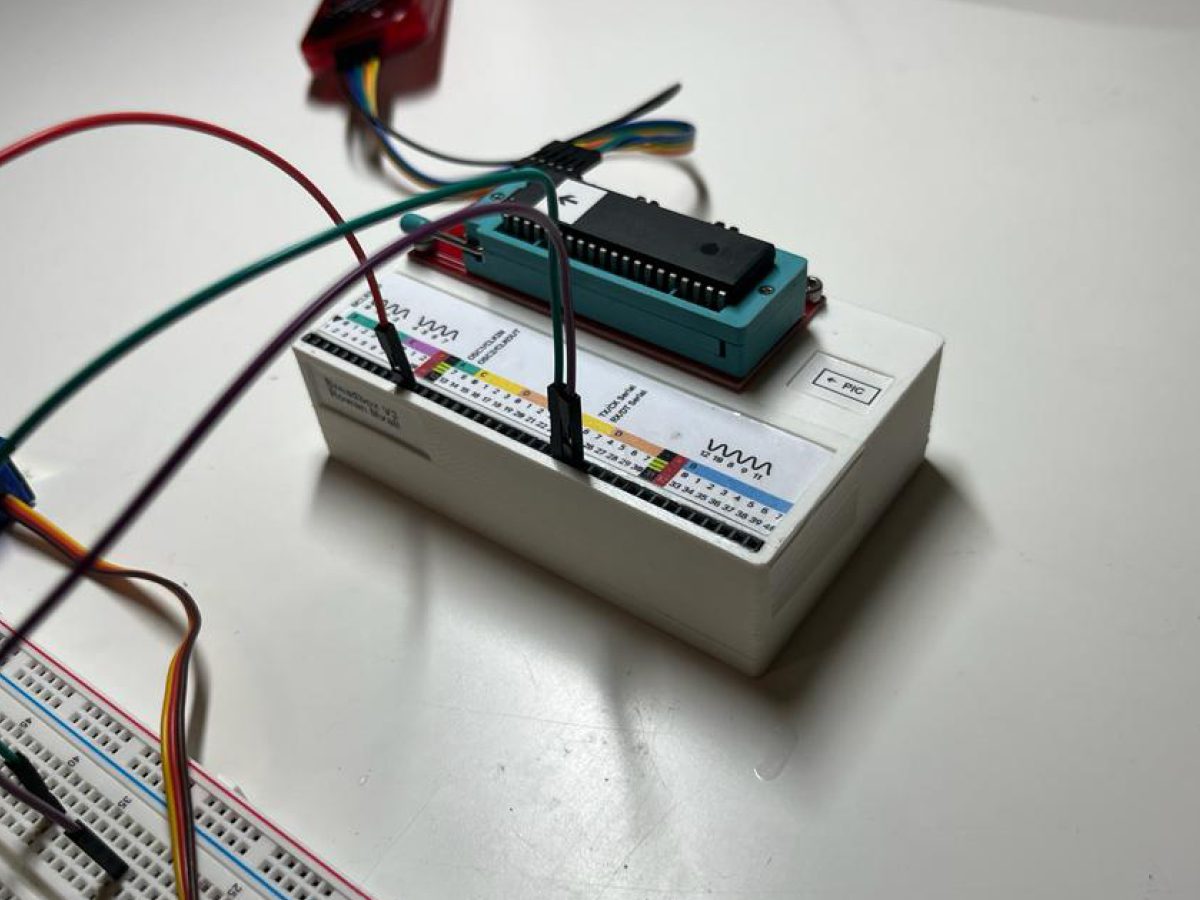

Breadbox V3

It’s an electronics project that makes teaching electronics easier. The PIC platform is great for learning low-level microcontroller programming, but it suffers from a lack of intuitiveness when compared to platforms like Arduino. The Breadbox (like a breadboard, but cooler) clearly diagrams the PIC’s 40 pins and their functions, and terminates them in female Dupont headers. The microcontroller comb makes swapping devices fast and easy.

Awards

- PDD Live Brief Award (2023)

- Triumph Innovation Award (2019)

- Diploma of International Studies

Work Experience

UW Designs (Feb-Aug 2022)

A design consultancy in North Wales and satellite office for Creo Medical. Delivered a working prototype of a medical device for non-invasive treatment of skin cancer. Managed and maintained the Formlabs and Prusa 3D printing platforms, supervised and proved g-code on the 5 axis milling machine.

Designing for Sustainability Transitions, TU Delft (Aug 2021 – Jan 2022)

Live project with Staatsbosbeheer (Dutch national parks service) to redesign the entrance area of Nationaal Park Nieuw Land using a systems thinking and sustainability-focussed approach.

Triumph Motorcycles (2019)

Work experience as winner of the 2019 innovation award.

Visionary Thinkers

Visionary Creators

Visionary Makers