Hi I'm Cai and I'm a Final Year Product Design Student. This year I challenged myself with a technical brief that excited my interests with electronics and user experience. This is what I've created.

Final Project

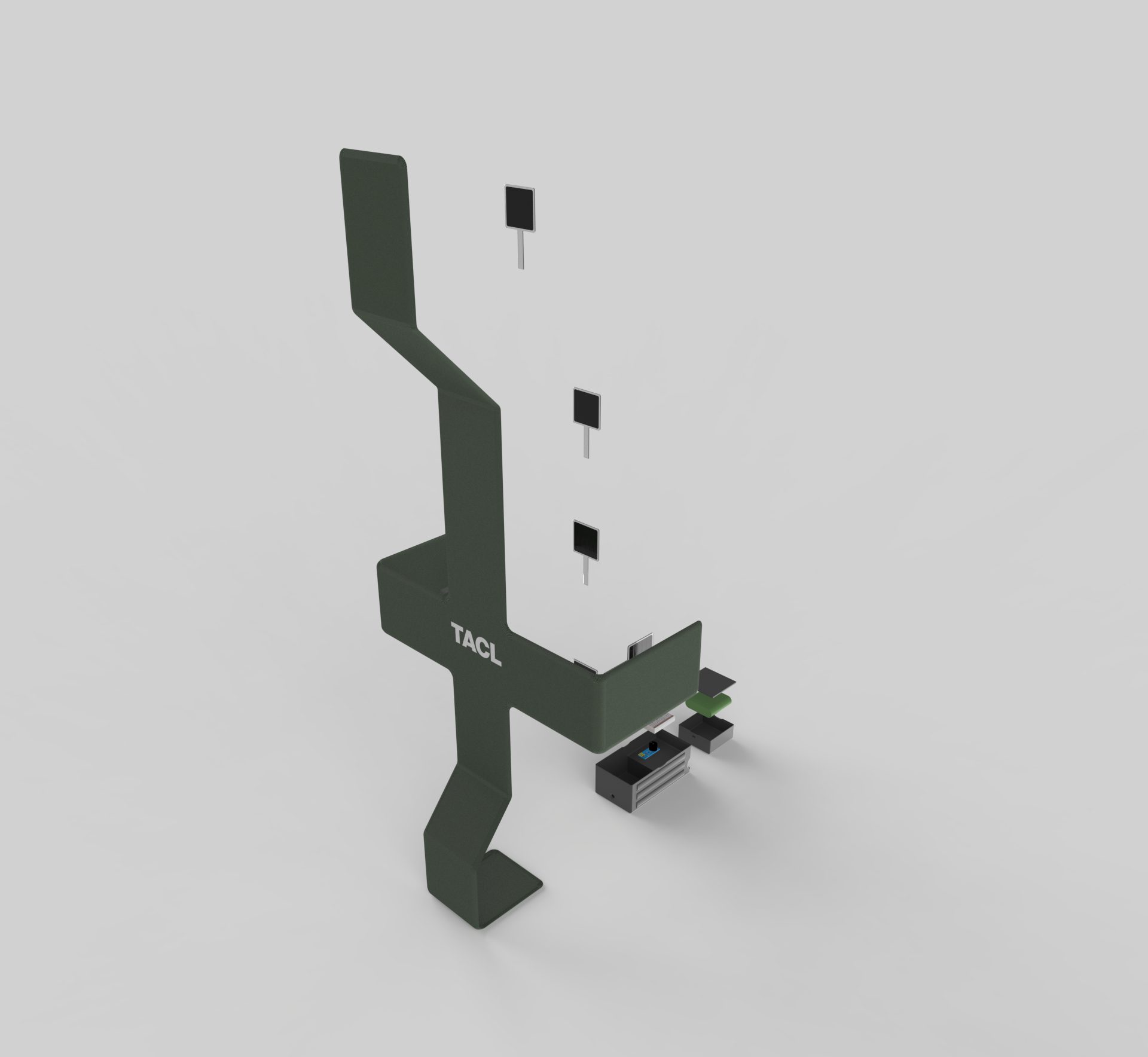

TACL

TACL has been made to deliver a service which allows rugby players and coaches to analyse poor tackle technique through retrofitting tackle bags with sensors and audio feedback. Over 50% of rugby injuries are caused by dangerous tackles and the recent realisation of high tackles within rugby is the perfect time to introduce this technology within tackle bags.

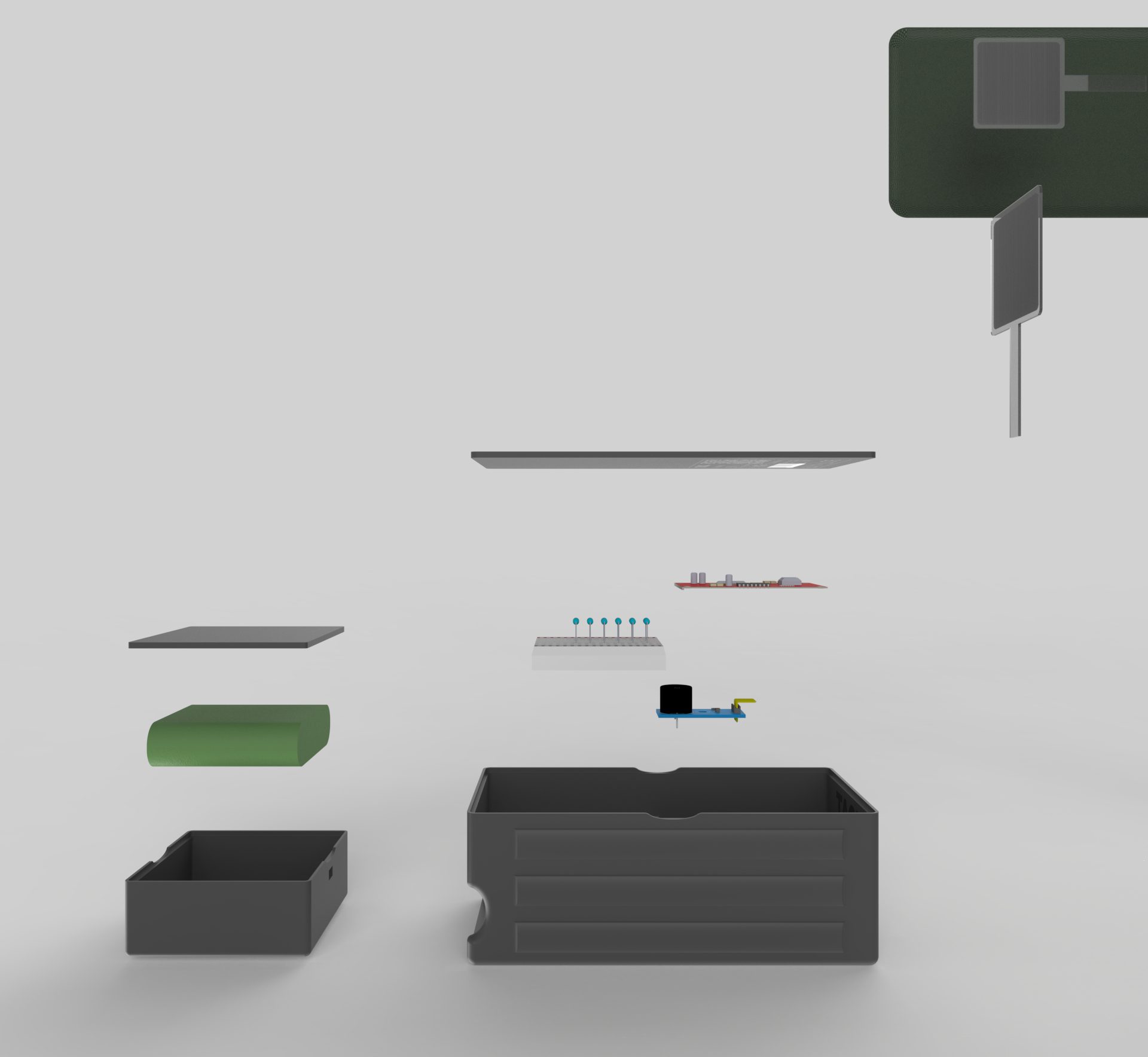

Embedded System

TACL uses force sensitive resistors that determine where on the tackle bag the rugby player has hit it. This new technology within the tackle bag will help prevent high and dangerous tackles in rugby by enforcing good practise and improving communication between rugby players and coaches. The system includes bluetooth to connect to devices, FSRs, a buzzer module and a microcontroller to control everything.

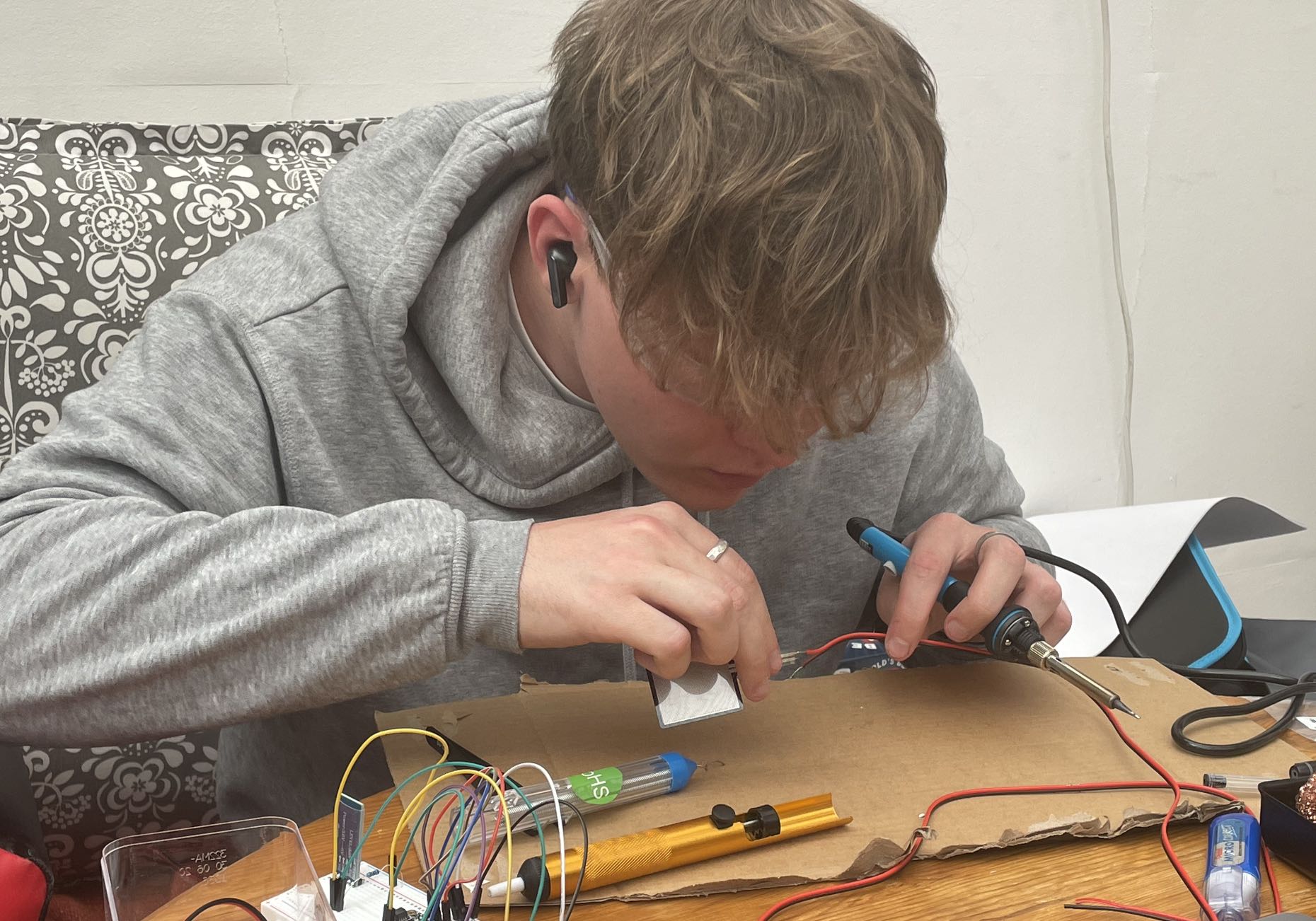

Prototyping

Prototyping was important for this project. I needed to create a functional prototype before user testing in order to see the value gained from TACL. This meant a lot of focus on creating the prototype though out the project – my electronics skills from Semester 1’s AeroPress project came in handy with this.

User Testing

A big focus on the project was User Testing. Seeing if this product is viable for rugby players and coaches. Research shows that there is a high interest in this product as it optimises the tackle bag and learnings from tackling.

Functionality

TACL senses impact from the FSRs and then either sends an instant audio feedback to the player, through a buzzer, and also sends instant feedback to the device connected to the bluetooth module within the hardware.

Electronics AeroPress Project

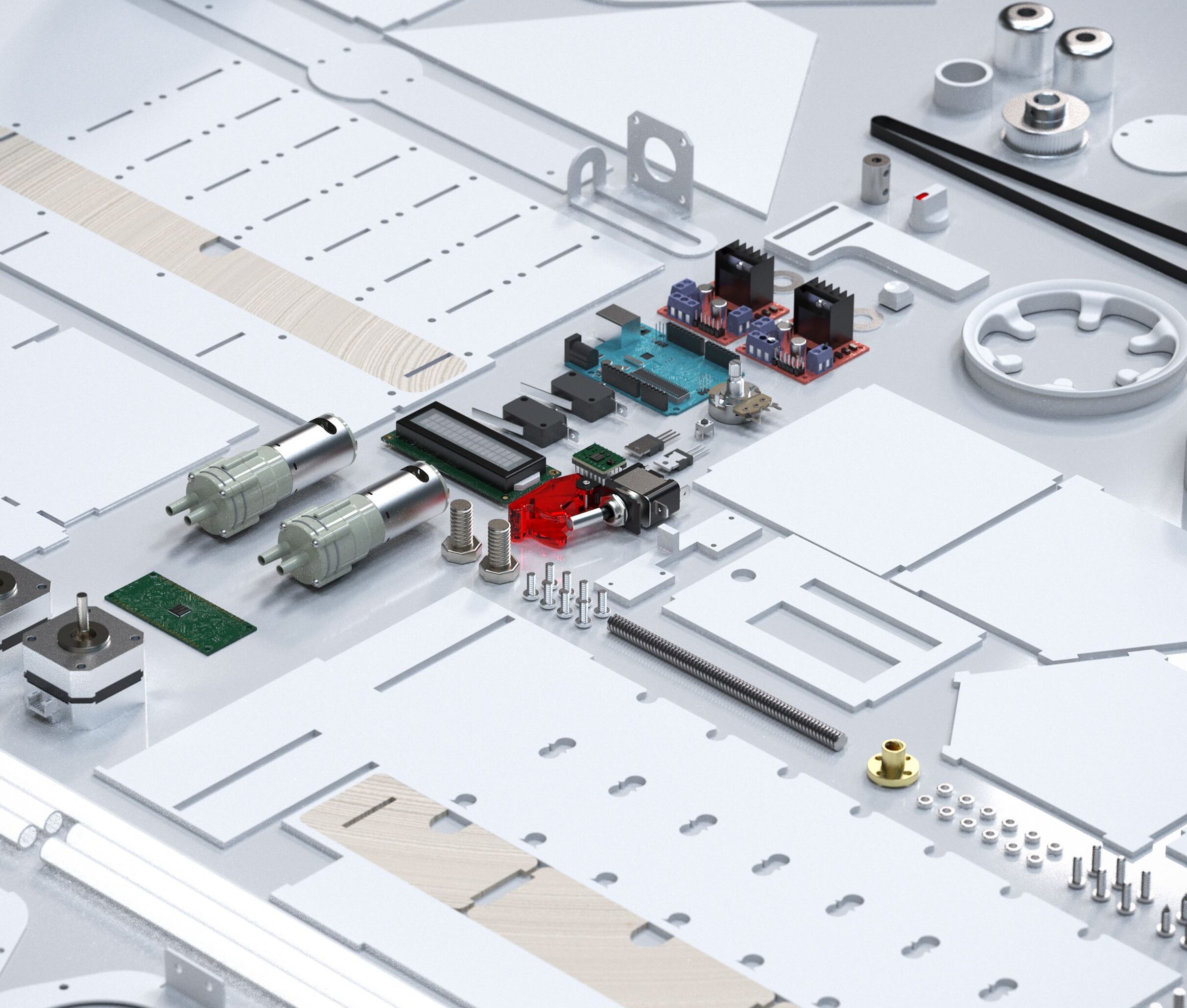

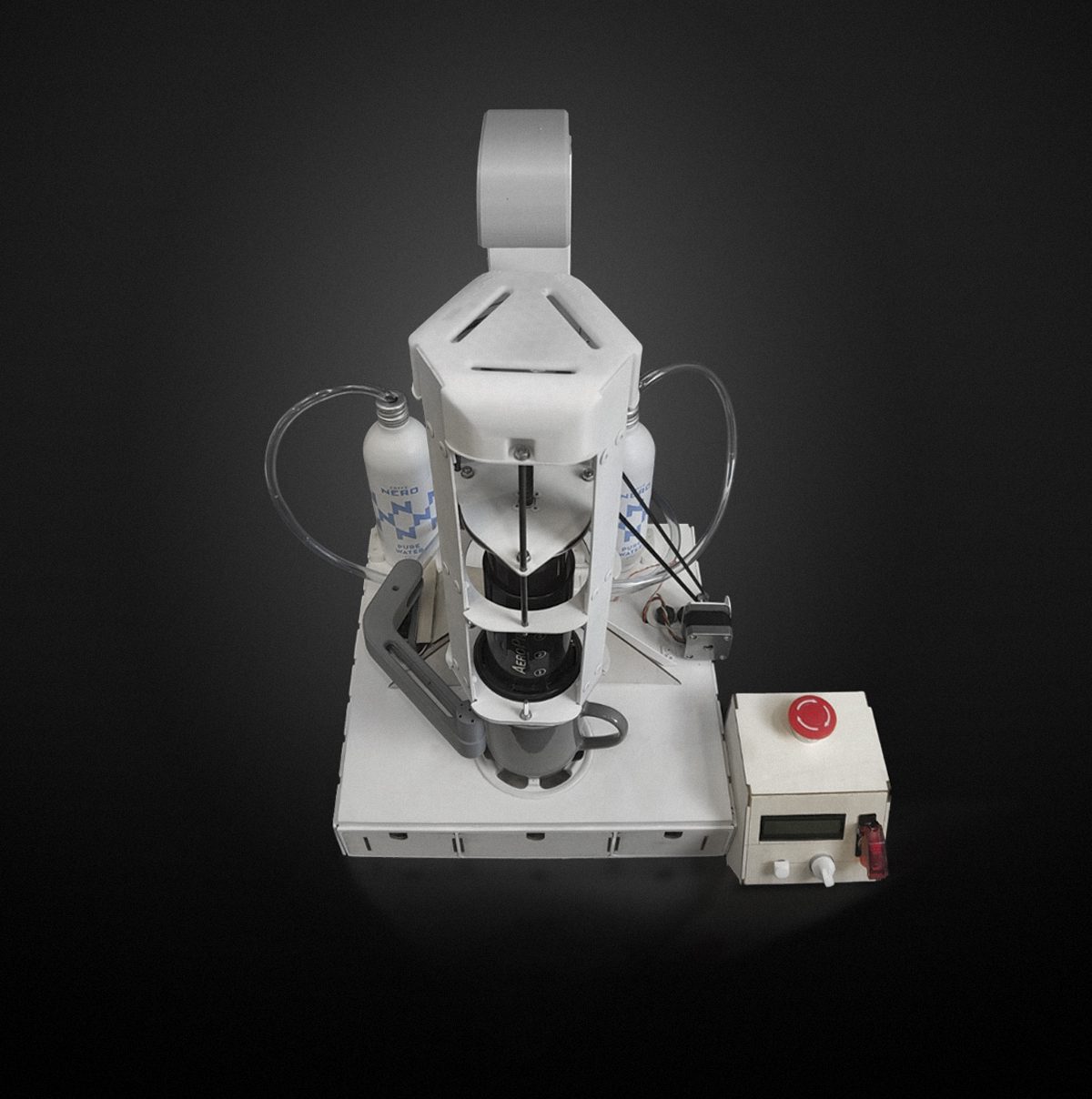

The Electronics AeroPress project was a group project to create a system that would create coffee automatically using an AeroPress. The group consisted of Thomas Dudgeon, Thomas Dixon, Thomas Briers and myself.

The group split up to to teams; Mechanical and Electronics. I was a part of the electronics and was responsible to create the code to make the Prototype fully functional. It consists over 800 lines of C code.

The final prototype could fill the AeroPress up with water, push the coffee out of the AeroPress with stepper motors and was even able to clean itself after using a PWM servo arm. In this project I gained the skills to create TACL.

Work Experience

I had the pleasure of working with Maersk Drilling in Copenhagen, Denmark for a year in their innovation department. Work consisted of User Experience, User Interfacing, User Testing and Graphic Design. I developed potential new products for the company whose main goal in the innovation department is to look at sustainable opportunities away from the Oil and Gas industry. I also created graphics throughout the departments in Maersk Drilling which allowed me to create great connections with the people there, which I still stay in touch with.

Visionary Thinkers

Visionary Creators

Visionary Makers